Working smarter to restore power

Powerco is installing smart technology on its overhead power lines to help get customers’ power back on more quickly when there is a fault.

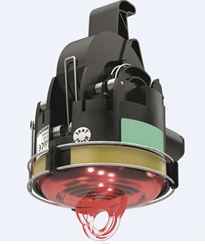

The six-year, $8.75 million investment, involves installing remote Line Fault Indicators (LFIs, pictured below) on overhead power lines throughout the electricity distribution company’s network.

Attached to the power lines between power poles, the device measures the power line’s current, voltage and temperature every 15 minutes. If there’s a fault on a section of line, the device will flash a light indicating the direction of the fault.

The device then uses the 4G network to report back to Powerco’s Network Operations Centre (NOC), Powerco General Manager Electricity Karen Frew says.

“These LFIs provide additional visibility in real time of what is happening on the network. Those in the control room can see where the fault is, so instead of sending a crew to patrol the whole feeder to find the fault, which could take several hours, we can quickly pinpoint the area of the feeder that is affected, isolate the fault, and get customers reconnected," General Manager Electricity Karen Frew says.

To date, Powerco has installed more than 300 devices on particularly fault-prone locations. The first remote LFIs – seven sets – were installed on the Cambridge Road feeder - a long, rural section of power line with a history of poor performance.

The company is working on providing more communications options for the technology, in addition to the 4G network, as coverage in more rural and isolated areas can be variable.

LFIs are a part of a wider rollout of automation technology, designed to reduce the impact of unplanned power outages on customers. It includes the increased use of remote control of switching points on the network, to be able to get the power back on sooner.

Below: Six Line Fault Indicators installed on power lines in the Coromandel region.